在纺织品中数字、字母、图标等标示类产品在热转印过程中极易产生变形,金运CAM高精度视觉识别系统专门针对此类问题,通过高精度的MARK点定位和软件具备的智能形变补偿算法来完成各种高要求热转印产品的**切割。

The most popular printing technology for textile materials is dye sublimation printing. The end result of sublimation of process is a nearly permanent, high resolution, full color print, the prints will not crack, fade or peel, while there will be distort, stretch of the materials when it is dye sublimated, it means the artworks shapes will change after sublimation printing. How can we get a precise shape as you want? It not only requires the registration system is with high precision, but also requires software has the function to amend the distorted shapes, this is especially important for making small logo, numbers, letters and other precise items.

Golden CAM camera registration technology will help you solve them. The camera is installed next to the laser head, we will print the fiducially marks around the printing shapes, the CCD camera will detect marks for positioning, after the camera detects all the marks, the software will adjust the original shapes according to the distortion materials, it ensures the high precision cutting result.

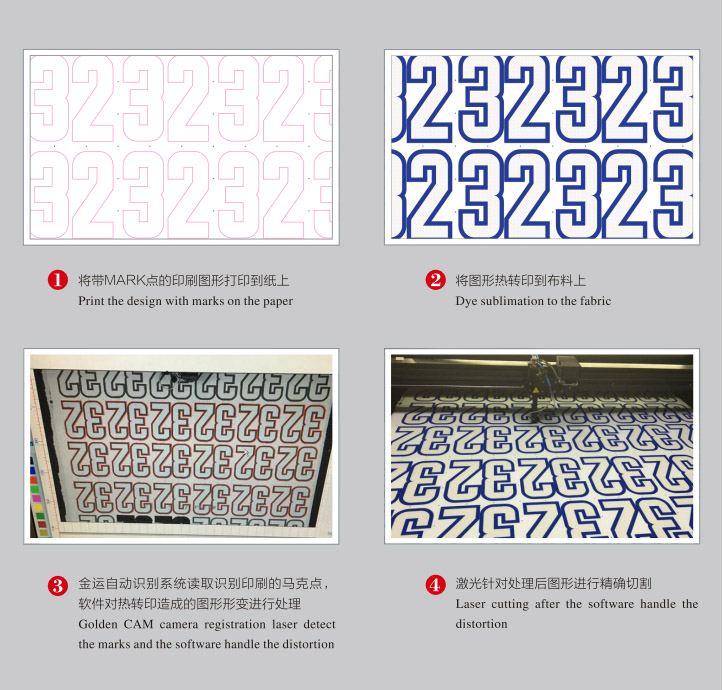

1将带mark点的图形打印到纸上 print the design with marks on the paper

2. 将图形热转印到布料上 dye sublimation to the fabric

3. 金运自动识别系统读取识别印刷的马克点,软件对热转印形成的图形形变进行处理 Golden CAM camera registration laser detect the marks and the software handle the distortion

激光针对处理后图形进行**切割 Laser cutting after software handle the distortion.